In the fast-paced world of packaging manufacturing, precision, efficiency, and innovation are the cornerstones of success. Maisheng Mold Manufacturing Factory has emerged as a trusted name in the industry, specializing in the design and production of high-performance PET preform molds and bottle cap molds for global clients. With a focus on cutting-edge technology, stringent quality control, and customer-centric solutions, Maisheng is driving advancements in packaging for industries ranging from beverages and cosmetics to pharmaceuticals and household chemicals.

1. Expertise in Preform Molds

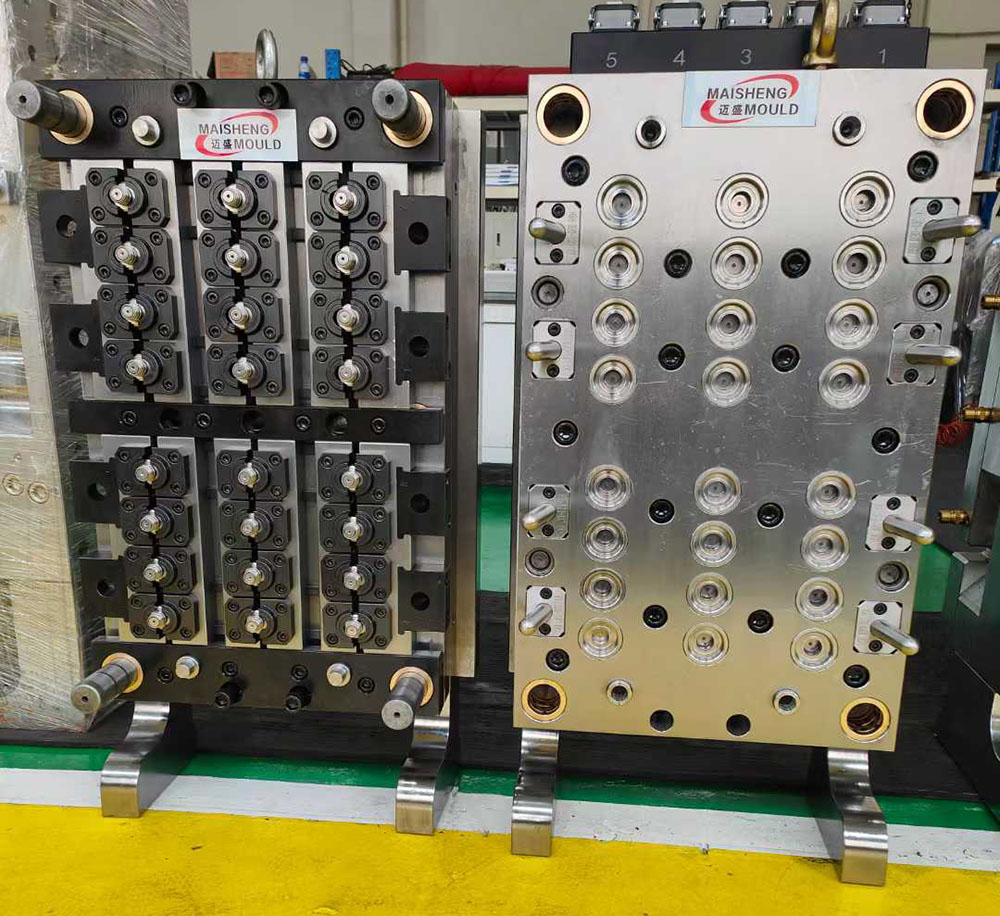

PET preforms are the foundational components of plastic bottles, and their quality directly impacts the integrity of the final product. Maisheng excels in manufacturing precision injection molds for PET preforms, tailored to meet the exacting demands of blow-molding processes.

Key Features:

Custom Design: Maisheng engineers molds for diverse applications, including water bottles, carbonated drink containers, and specialty packaging (e.g., hot-fill or UV-resistant preforms).

Material Optimization: Molds are crafted from hardened tool steels (H13, stainless steel) with advanced coatings to enhance durability and thermal management.

Neck Finish Precision: Compatibility with industry-standard finishes like PCO 1881, BPF, and custom threads ensures leak-proof closures.

High-Cavitation Molds: Designed for high-speed production, supporting up to 144 cavities to maximize output for large-scale bottling operations.

2. Bottle Cap Mold Manufacturing Excellence

Bottle caps may seem simple, but their design requires meticulous engineering to ensure functionality, safety, and consumer convenience. Maisheng’s bottle cap molds are synonymous with reliability and innovation.

Key Capabilities:

Material Versatility: Molds for HDPE, PP, and other polymers, catering to screw caps, flip-top lids, and child-resistant closures.

Thread Accuracy: Precision-machined threads and tamper-evident features to meet global standards (e.g., ISO 9001, FDA compliance).

Multi-Cavity Solutions: High-cavitation molds (48–96 cavities) for cost-effective mass production.

Customization: Designs for specialty applications, such as carbonated beverage caps with pressure-resistant seals or cosmetic caps with integrated applicators.

3. Advanced Technology and Innovation

Maisheng leverages state-of-the-art manufacturing technologies to stay ahead in a competitive market:

CNC Machining & EDM: Ensures micron-level precision in mold components.

Moldflow Simulation: Software-driven analysis to predict flow behavior, cooling efficiency, and stress points, minimizing trial-and-error.

Conformal Cooling Channels: Optimized cooling systems reduce cycle times and energy consumption while preventing defects like warping.

Automation Integration: Molds compatible with robotic ejection systems and Industry 4.0-ready production lines.

4. Quality Assurance and Compliance

Maisheng’s commitment to quality is unwavering:

Certifications: Compliance with FDA, EU 10/2011, REACH, and other food-contact safety regulations.

Material Traceability: Full documentation of raw materials and coatings for audits.

Durability Testing: Molds rigorously tested for lifespan (1–5 million cycles) under high-pressure injection conditions.

Third-Party Inspections: Collaborate with global partners to validate dimensional accuracy and performance.

5. Global Clientele and Industry Applications

Maisheng serves a diverse range of industries worldwide:

Beverages: PET preforms for water, juices, and carbonated drinks.

Pharmaceuticals: Tamper-evident caps and medical-grade preforms.

Cosmetics: Aesthetic, lightweight caps and luxury packaging molds.

Household Chemicals: Chemical-resistant closures for detergents and cleaners.

The company’s clients span Asia, Africa, Europe, and the Americas, with a reputation for delivering cost-effective solutions without compromising on quality.

6. Customization and After-Sales Support

Understanding that no two clients are alike, Maisheng emphasizes bespoke solutions:

R&D Collaboration: Work directly with clients to prototype and refine designs.

Rapid Prototyping: 3D-printed mold samples for pre-production validation.

Maintenance Services: Lifelong technical support, mold repairs, and refurbishment to extend tooling lifespan.

Why Choose Maisheng?

Cost Efficiency: Competitive pricing without sacrificing precision, ideal for startups and established brands alike.

Speed-to-Market: Streamlined production processes and fast lead times (8–12 weeks for standard molds).

Sustainability Focus: Designs that minimize material waste and energy consumption.

End-to-End Solutions: From mold design to post-production support, Maisheng is a single-point partner.

Conclusion

In an era where packaging demands are evolving rapidly—driven by sustainability trends, regulatory changes, and consumer preferences—Maisheng Preform Mold and Bottle Cap Mold Manufacturing Factory stands out as a leader in innovation and reliability. By combining engineering expertise with a deep understanding of global market needs, Maisheng empowers brands to deliver safe, functional, and visually appealing packaging solutions.

For businesses seeking a partner that prioritizes precision, scalability, and long-term value, Maisheng is poised to meet the challenges of today’s dynamic packaging landscape.