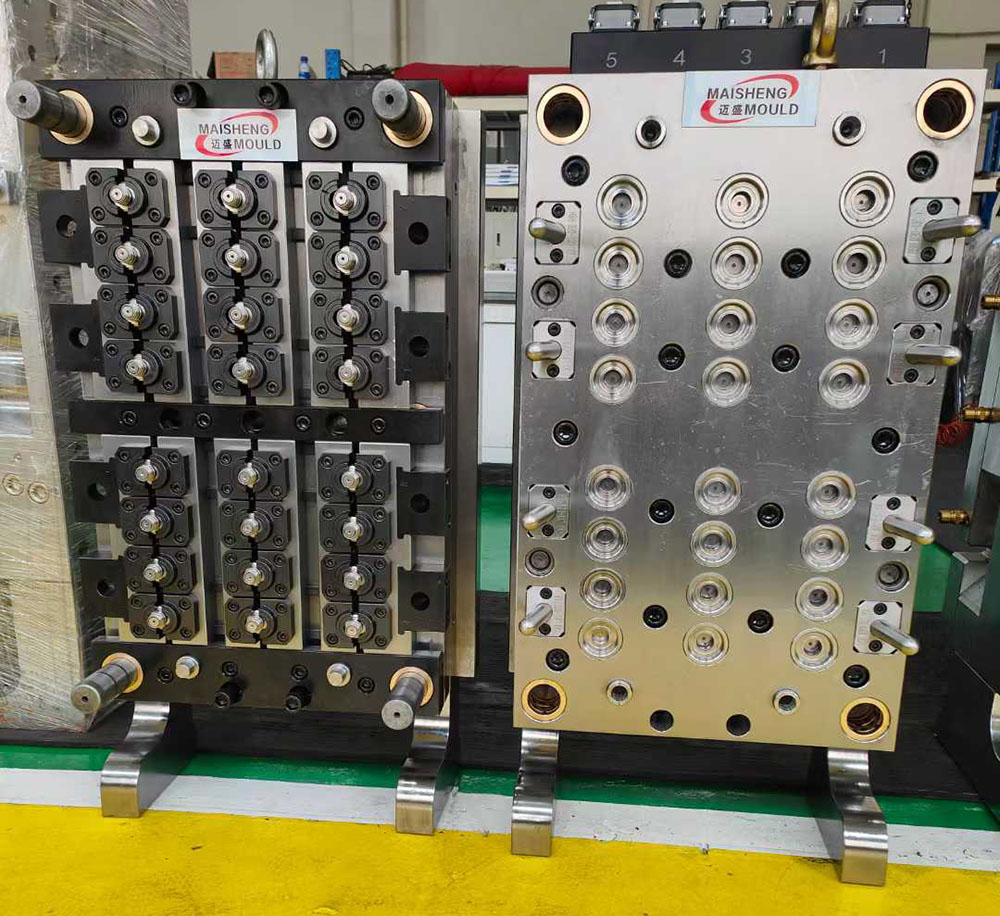

Stainless steel mold plates for corrosion resistance and easier mold maintenance

Ejection sensors monitor preform transfer to the PET preform take-off plate improving cycle time

Standard interchangeable mold components, replacement parts available

Separately cooled neck rings lead to high preform quality at short cycle times, improve dimensional stability of threads

Perfectly balanced hot runners that ensure uniform melt flow and homogenous pressure in all cavities resulting in precise preform weight stability.

A well-balanced cooling channel layout and turbulent water flow, results very consistent cooling and efficient heat transfer away from the preforms.

Optimum preforms cooling technology for fast cycles and increased productivity

With air-assisted locking rings, preform ejection (blow out)