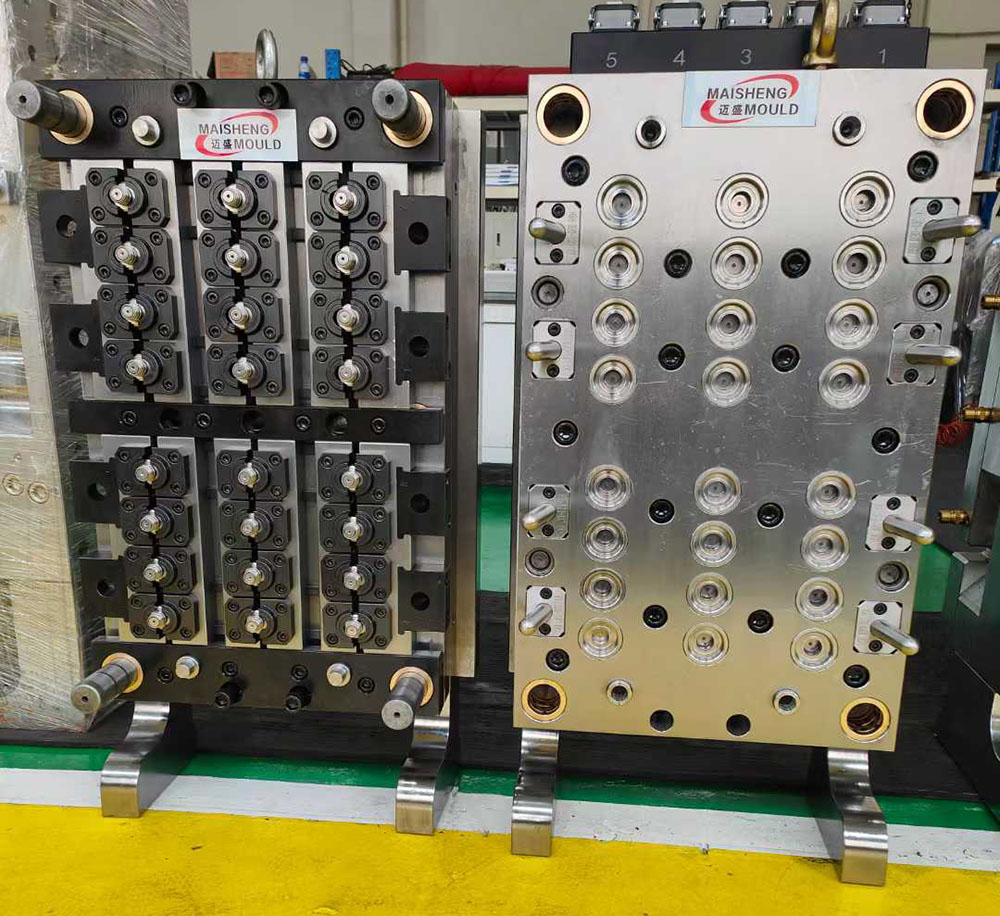

Maisheng company has been committed to researching and manufacturing hot runner PET preform mould with independent self-lock system. We have mould specification of 8cavity, 12cavity, 16cavity Preform Molds,24cavity Preform Molds, 32 cavity Preform Molds, 48cavity Preform Molds and 72 cavity Preform Molds.

Mould Specification

| Cavity Number | 22g Preform Length:94mm | 32g Preform Length:120mm | 42g Preform Length:130mm | |||

| Dimension(mm) | Weight(kg) | Dimension(mm) | Weight(kg) | Dimension(mm) | Weight(kg) | |

| 4(1*4) | 500*290*430 | 550 | 500*290*445 | 600 | 500*290*455 | 680 |

| 6(2*3) | 430*370*400 | 760 | 430*370*415 | 850 | 430*370*425 | 900 |

| 8(2*4) | 490*370*435 | 810 | 490*370*450 | 900 | 490*370*460 | 970 |

| 12(2*6) | 630*370*435 | 1020 | 630*370*450 | 1100 | 630*370*460 | 1180 |

| 12(2*8) | 750*370*480 | 1240 | 750*370*495 | 1350 | 750*370*505 | 1450 |

| 24(3*8) | 830*440*500 | 1880 | 830*440*515 | 1950 | 830*440*525 | 2060 |

| 32(4*8) | 830*580*515 | 2360 | 830*580*530 | 2250 | 830*580*545 | 2600 |

| 48(4*12) | 1065*580*525 | 2930 | 1065*580*540 | 3050 | 1065*580*555 | 3150 |

| 72(6*12) | 1140*830*560 | 4320 | 1140*830*575 | 4450 | 1140*830*580 | 4600 |

Product Description

Our company has been committed to researching and manufacturing hot runner PET preform mould with independent self-lock system. We have mould specification of 8cavity, 12cavity, 16cavity,24cavity, 32 cavity, 48cavity and 72 cavity. The bottle neck size can be PCO1810, ISBT1881, 30/25, 29/25, 38MM, 26MM and other custom made size.

PET Preform Mould Feature

1. High effiency and Low cost

using Germany heating ring HOTSET only 268W, the traditional one 320W, save 20% electricity cost. Lower AA level and be more environmental.

Hot runner production, save labor cost. One worker can work for 3 or 4 sets of injection machine

Large diameter pipe make the mould cool fast and well. Shorten cycle time.

Adopt double ejection device, pulley sliding and ejector sleeve to make sure the preform can be ejected smoothly without the robot hand.

2. Durable

Use P20 pre-hardened steel as the pet preform mould plate to make complete structure stable, not easy transformation.

All the mould plate rust-proof handling, decrease the second pollution during the production.

Core, cavity and screw all use S136 stainless steel. After the vacuum treatment, hardness 48-50HRC.

Guarantee: 3million shots.

3. High Accuracy and Easy maintaince

With high precision imported machine tool, all the spare parts can be interchanged to save the maintaince time and guarantee the preform weight difference.

Independent hot runner system, even one cavity is broken, others still work.

The temperature controller is controlled by PID. It can be changed on working condition.

Core, cavity and neck screw is controlled by the double cone positioning to ensure does not appear flash, different size, irregualr and other defects.